Idayimitha enkulu spiral metal umbhobho umenzi

a.Ngethuba lenkqubo yokuqulunqa, ipleyiti yensimbi ikhubazekile ngokulinganayo, uxinzelelo olushiyekileyo luncinci, kwaye umphezulu awukhatywanga. Umbhobho wentsimbi ecociweyo uguquguquka ngakumbi kubungakanani kunye noluhlu oluchaziweyo lobubanzi kunye nobukhulu bodonga, ngakumbi kwimveliso yombhobho ongqingqwa wodidi oluphezulu, ngakumbi umbhobho ongqindilili omncinci nophakathi, onezinto ezilungileyo ezingenakuthelekiswa nezinye iinkqubo, kwaye inokuhlangabezana neemfuno ezininzi zabasebenzisi kwinkcazo yombhobho wentsimbi ejikelezayo.

b. Inkqubo yokudibanisa i-arc enecala eliphindwe kabini iyakwazi ukuqonda i-welding kwindawo engcono kakhulu, engelula ukuba ibe neziphene ezifana nokungahambi kakuhle, ukuphambuka kwe-welding kunye nokungena okungaphelelanga, kwaye kulula ukulawula umgangatho we-welding.

c. Ukuhlolwa kwekhwalithi ye-100% kuqhutyelwa kumbhobho wensimbi, ukwenzela ukuba yonke inkqubo yokuvelisa umbhobho wensimbi iphantsi kokubonwa okusebenzayo kunye nokubeka iliso, kwaye umgangatho wemveliso uqinisekisiwe ngokufanelekileyo.

d. Zonke izixhobo zomgca wemveliso yonke inomsebenzi wokunxibelelana kunye nenkqubo yokufumana idatha yekhompyutheni ukuqonda ukuhanjiswa kwedatha yexesha langempela, kwaye iiparitha zobugcisa kwinkqubo yokuvelisa zijongwa yigumbi lokulawula eliphakathi.

Umbhobho wentsimbi ojikelezayo uya kuba phantsi kovavanyo lwepropathi yomatshini, uvavanyo lokucaba kunye novavanyo lokuvutha phambi kokuba ushiye umzi-mveliso, kwaye uya kuhlangabezana neemfuno ezichazwe kumgangatho. Indlela yokuhlola umgangatho wombhobho wentsimbi yomthungo othe tye yile ilandelayo:

1.Ukugweba kumphezulu, oko kukuthi, ekuhloleni imbonakalo. Ukuhlolwa kwembonakalo yamalungu adibeneyo yindlela yokuhlola elula kwaye esetyenziswa ngokubanzi. Ingumxholo obalulekileyo wokuhlolwa kwemveliso egqityiweyo. Ikakhulu kukufumana iziphene kumphezulu we-weld kunye nokutenxa kwe-dimensional. Ngokuqhelekileyo, ukuhlolwa kwenziwa ngokujongwa okubonakalayo ngoncedo lwetemplate eqhelekileyo, igeji, iglasi yokukhulisa kunye nezinye izixhobo. Ukuba kukho iziphene kwi-weld surface, kunokubakho iziphene ngaphakathi kwi-weld.

2.Uvavanyo lwendlela yomzimba: indlela yovavanyo lomzimba yindlela yokulinganisa okanye yokuvavanya ngokusebenzisa isenzeko esithile somzimba. Uvavanyo olungonakalisiyo lusetyenziswa ngokubanzi ukuhlola iziphene zangaphakathi zemathiriyeli okanye izixhobo zokusebenza. I-NDT ibandakanya ukufunyaniswa kwesiphene se-ultrasonic, ukubonwa kwesiphene se-radiographic, ukubonwa kwesiphene esingena ngaphakathi, ukubonwa kwempazamo yamagnetic, njl.

3.Uvavanyo lwamandla eenqanawa zoxinzelelo: ukongeza kuvavanyo lokuqina, uvavanyo lwamandla luya kwenziwa kwakhona kwiinqanawa zoxinzelelo. Kukho iindidi ezimbini eziqhelekileyo: uvavanyo lwe-hydrostatic kunye novavanyo lwe-pneumatic. Banokuvavanya ukuqina kwe-weld kwiinqanawa kunye nemibhobho esebenza phantsi koxinzelelo. Uvavanyo lwe-pneumatic lubuthathaka kwaye lukhawuleza kunovavanyo lwe-hydraulic. Ngexesha elifanayo, iimveliso ezivavanyiweyo azidingi unyango lokukhupha amanzi, olufanelekileyo ngokukhethekileyo kwiimveliso ezinobunzima bokuhambisa amanzi. Kodwa uvavanyo luyingozi ngakumbi kunovavanyo lwe-hydrostatic. Ngexesha lovavanyo, amanyathelo okhuseleko ahambelanayo kufuneka ajongwe ukukhusela iingozi ngexesha lovavanyo.

4.Uvavanyo lokuxinana: kwiinqanawa ezidityanisiweyo ezigcina ulwelo okanye irhasi, iziphene ezinganyangekiyo zeewelds, ezinje ngokugqobhoza kweentanda, iipores, ukufakwa kwe-slag, ukungena okungaphelelanga kunye nokwakheka okuxekethileyo, kunokufunyanwa ngovavanyo lokubumbana. Iindlela zokuvavanya ukubumbana ziquka uvavanyo lweparafini, uvavanyo lokuthwala amanzi, uvavanyo lwempembelelo yamanzi, njl.

5.Uvavanyo lwe-hydrostatic, umbhobho ngamnye wensimbi uya kuba phantsi kovavanyo lwe-hydrostatic ngaphandle kokuvuza. Uxinzelelo lovavanyo luya kubalwa njenge-P = 2st / D, apho s - Uvavanyo loxinzelelo lweMPa yovavanyo lwe-hydrostatic, kunye noxinzelelo lovavanyo lovavanyo lwe-hydrostatic luya kukhethwa njenge-60% yexabiso elincinci lesivuno elichazwe kumgangatho ohambelana nentsimbi yebhanti (Q235) yi 235mpa. Ixesha lokuzinzisa uxinzelelo: D. i-spiral weld yombhobho wensimbi wokuhanjiswa kwamanzi kuya kuxhomekeka kwi-X-ray okanye ukuhlolwa kwe-ultrasonic (20%).

Ngokweziphumo zokuhlola umgangatho we-spiral steel pipe, i-spiral steel pipe idla ngokwahlulahlulwe ngokwamacandelo amathathu: iimveliso ezifanelekileyo, iimveliso ezilungisiweyo kunye nenkunkuma. Iimveliso ezifanelekileyo zibhekiselele kwimibhobho yentsimbi ejikelezayo ekubonakala kwayo umgangatho kunye nomgangatho wangaphakathi uhlangabezana nemigangatho efanelekileyo okanye iimeko zobugcisa zokwamkelwa kokunikezelwa; Iimveliso ezilungisiweyo zibhekiselele kwimibhobho yensimbi ejikelezayo ebonakala ngathi umgangatho kunye nomgangatho wangaphakathi awuhambisani ngokupheleleyo nemigangatho kunye neemeko zokwamkelwa, kodwa zivumelekile ukuba zilungiswe, kwaye zinokuhlangabezana nemigangatho kunye neemeko zokwamkelwa emva kokulungiswa; I-Scrap ibhekisela kumbhobho wensimbi ojikelezayo obonakala umgangatho kunye nomgangatho wangaphakathi awufanelekanga, ongavumelekanga ukuba ulungiswe okanye usahluleka ukuhlangabezana nemigangatho kunye neemeko zokwamkelwa emva kokulungiswa.

Iimveliso zenkunkuma zahlulwe zibe yinkunkuma yangaphakathi kunye nenkunkuma yangaphandle. Inkunkuma yangaphakathi ibhekiselele kumbhobho wentsimbi ojiyileyo ofunyenwe kwindawo esisiseko okanye kwindawo yokusebenzela; Inkunkuma yangaphandle ibhekiselele kwinkunkuma efunyenwe emva kokunikezelwa kombhobho wensimbi ojikelezayo, odla ngokuvezwa kwinkqubo yokucoca, unyango lobushushu okanye ukusetyenziswa, kwaye ilahleko yayo yezoqoqosho inkulu kakhulu kunenkunkuma yangaphakathi. Ukuze kuncitshiswe inkunkuma yangaphandle, imibhobho yentsimbi evunguzayo eveliswe ngokweebhetshi kufuneka ithathwe iisampulu yovavanyo lonyango lobushushu kunye nolungiso olurhabaxa ngaphambi kokuba ushiye umzi-mveliso, kwaye iziphene ezinokubakho zentsimbi yombhobho wentsimbi kufuneka zifunyanwe kwiplanti yentsimbi ejikelezayo kangangoko kunokwenzeka. njengokuthatha amanyathelo okulungisa ayimfuneko ngokukhawuleza kangangoko.

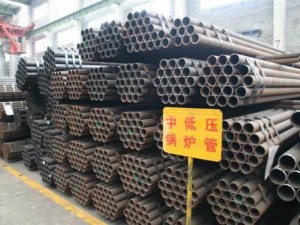

1) Intsimbi yecandelo elincinci neliphakathi, intsimbi, intonga, ukuqinisa, umbhobho wentsimbi ophakathi, intambo yentsimbi kunye nentambo yentsimbi inokugcinwa kwishedi engena umoya, kodwa kufuneka igqunywe kwaye ifakwe.

2) Enye intsimbi encinci, ishidi lentsimbi, intsimbi yentsimbi, i-silicon sheet, i-tadium-diameter encinci okanye umbhobho wensimbi obhityileyo, iintsimbi ezahlukeneyo eziqengqelekayo nezibandayo kunye neemveliso zetsimbi ezinexabiso eliphezulu kunye nokubola okulula kunokugcinwa kwindawo yokugcina impahla.

3)Isiza okanye indawo yokugcina iimveliso zemibhobho yentsimbi ejikelezayo iya kuba kwindawo ecocekileyo nengaphazanyiswayo, kude neefektri kunye nemigodi evelisa irhasi eyingozi okanye uthuli. Ukhula kunye nazo zonke ii-sundriries ziya kususwa kwisiza ukugcina intsimbi icocekile.

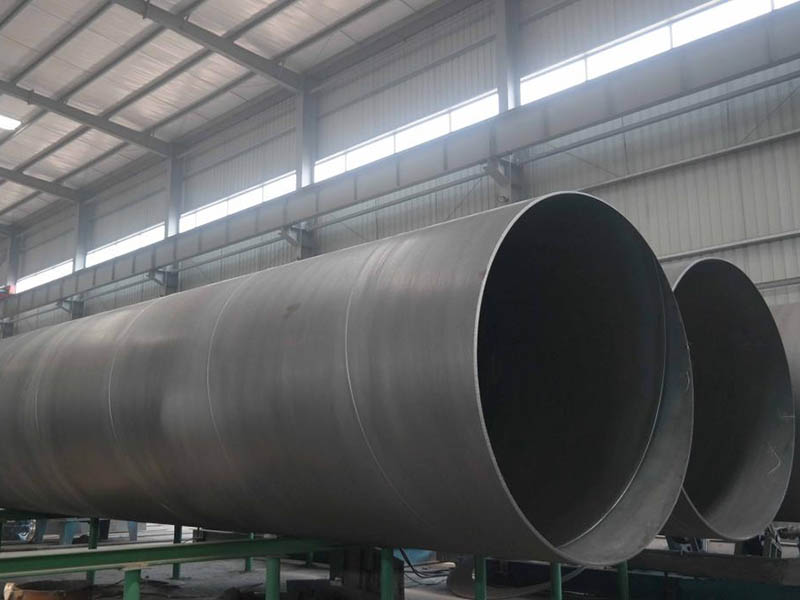

4) Intsimbi yecandelo elikhulu, umzila wesitimela, ipleyiti yensimbi, umbhobho wensimbi we-diameter enkulu, i-forging, njl.

5)Akuvumelekanga ukupakishwa nge-asidi, i-alkali, ityuwa, i-samente kunye nezinye izinto ezinobungozi kwintsimbi kwindawo yokugcina impahla. Iindidi ezahlukeneyo zentsimbi ziya kupakishwa ngokwahlukileyo ukuze kuthintelwe ukudideka kunye nokudibana nokubola.

6)Indawo yokugcina impahla iya kukhethwa ngokweemeko zejografi. Ngokuqhelekileyo, ithatha indawo yokugcina impahla evaliweyo, oko kukuthi, indawo yokugcina impahla enophahla, indawo ebiyelweyo, iingcango eziqinileyo kunye neefestile kunye nezixhobo zokungenisa umoya.

7) Indawo yokugcina impahla iya kufakwa umoya ngeentsuku ezinelanga, ivalwe ngeentsuku zemvula ukuthintela ukufuma, kwaye isoloko igcina indawo efanelekileyo yokugcina indawo.